Turning plastic waste into concrete

Concrete is a vital construction material but its production creates significant greenhouse gas emissions (estimated to make up 8–10% of the world’s emissions). Two projects funded by Sustainability Victoria bring together universities and industry to create new markets for recycled plastics and new concrete products that are both durable and sustainable.

A-void using virgin materials

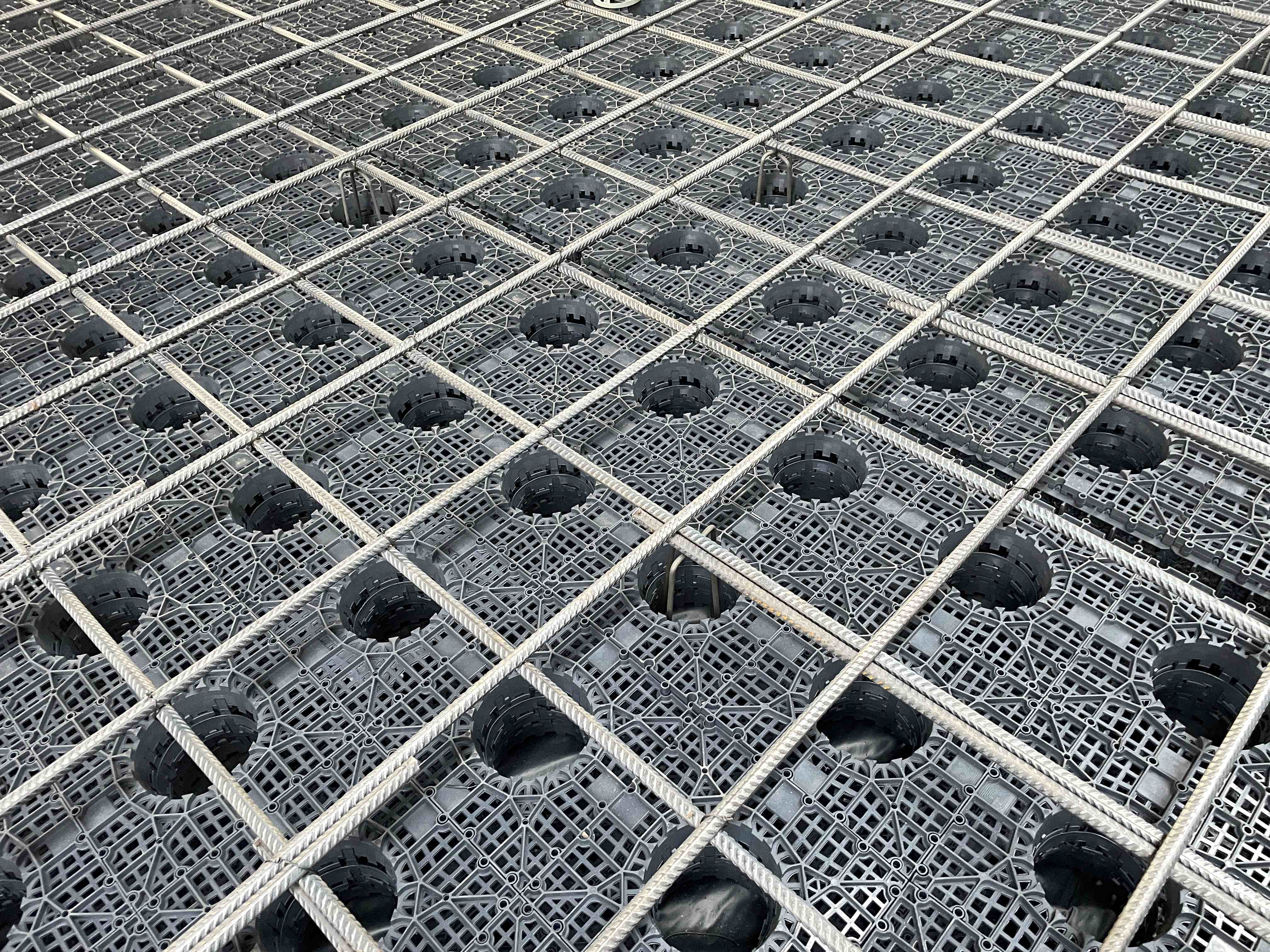

Robovoid system for concrete ground slab installation.

Robovoid system for concrete ground slab installation. Void formers are used in many construction projects, including building foundations, bridges, and roadways. As well as helping to manage ground pressure and improve structural efficiency, they can reduce the amount of concrete needed by up to 70%.

Melbourne-based company Robovoid has created a void former made from 100% recycled plastic from used grain farming bunker tarp, replacing virgin materials like polystyrene.

Sustainability Victoria provided $175,000 to Swinburne University to research and develop the product in partnership with Robovoid. This led to further research funding of $2.4 million from the Australian Government’s Cooperative Research Centres Projects Grants to further develop the product.

Sustainability Victoria’s Manager Markets Acceleration Shannon Smyth said that after their research success the team looked to commercialise the product with another $300,000 in funding from SV to Robovoid.

‘Government has an important role to play in accelerating the commercialisation of recycled products like the Robovoid void formers. Once new recycled products have been commercialised and are self-sustaining, we let market forces take over. This initial support is essential to our transition to a net-zero circular economy.’

The Victorian Government’s Big Build is optimising the use of recycled materials in construction and has already incorporated the recycled void formers into the Keon Park level crossing and station redevelopment, which opened in June 2024. And they have even proven useful in bed bases.

Turning high-vis vests into concrete

The team from Victoria University and Laing O'Rourke trialling their novel concrete design with textile and kraft fibres.

The team from Victoria University and Laing O'Rourke trialling their novel concrete design with textile and kraft fibres. Every year Australia throws out 11,000 tonnes of textile waste in the form of uniforms, including high-visibility vests. Their fluoro materials and reflective strips in the vests fade over time and need to be replaced every six months. 99% of uniforms end up in landfill.

A partnership between Victoria University and social enterprise Assembled Threads, has created an innovative solution to transform old polyester vests into new footpaths.

Associate Professor Dr Malindu Sandanayake and his team designed the perfect mix of cardboard and textiles that can replace virgin cement with a product containing recycled materials.

The textiles come from Assembled Threads, who turn old high-vis vests into new ones. They’re providing off-cuts from this process to the Victoria University team for what they’re calling 'tex-crete'.

‘It is as strong, almost more so, than a traditional cement composition,’ says Dr Sandanayake.

‘This fibre will not break down in the natural environment, so we thought we could capitalise on the strength of it to replace other polluting materials that are traditionally in concrete, such as cement.

‘This mix is safe, durable and improves our climate footprint. It is also cost-effective due to the low-carbon conversion process of sustainable composite and the use of landfill waste material as a cement replacement material,’ says Dr Sandanayake.

Shannon Smyth said that Sustainability Victoria has a vital role to play by working with universities and industry to research and develop new uses for recycled materials.

'As a relatively new sector, demand for construction products containing recycled materials is still emerging. That’s why government has an important role to play in getting the word out there about these sustainable products and reducing some of the risk for Victoria’s innovators and first movers in the circular economy.'

Sustainability Victoria has awarded $16 million in grants to over 90 projects to research, develop, demonstrate, commercialise and use recycled materials and products.

Researchers are invited to come along to an event on 10 October 2024 to talk about commercialisation and investment attraction challenges and opportunities, and to network with government and university colleagues.